In recent years, the European Union has gradually issued restrictions on per- and polyfluoroalkyl substances (PFAS) to reduce their impact on the environment and human health.

Fine chemicals produce complex molecules from organic or mineral intermediates, the result of numerous chemical reactions in series. The corresponding industrial units generally operate on a batch basis. They involve a series of complex reactions with frequent operational changes (nature of solvents, pressure and temperature conditions, etc.). Filtration, in the broadest sense of the term, affects raw materials, intermediates and finished products, and is therefore an intrinsic part of the process.

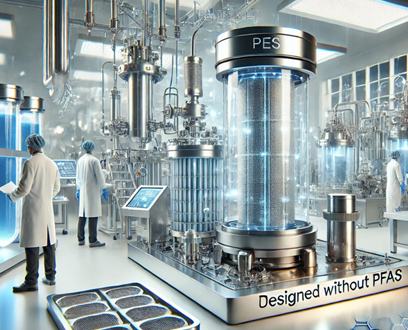

The biopharmaceutical industry is increasingly using disposable single-use systems for the development and manufacture of a wide range of vaccines, therapeutic proteins and monoclonal antibodies (Mab's). What devices are available on the market ? What advantages do they offer ? And for which applications ? Techni Filtration takes stock.

Constrained by a strict regulatory framework, the management of water for pharmaceutical use is the focus of much attention from professionals in the sector. But guaranteeing the microbiological cleanliness of your purified water installation is a real challenge. The main cause is the micro-organisms lining the walls of the circuit which, escaping any dosage, threaten the conformity of the system.